Resistance of plastic pipes: PE and PVC in direct comparison

Thanks to their properties and characteristics, plastic pipes made of polyethylene (PE) and polyvinyl chloride (PVC) have already established themselves as permanent fixtures in industry and infrastructure. Their chemical resistance, corrosion resistance and durability of up to 100 years make them ideal for applications in drinking water supply, wastewater disposal and industrial applications that require particularly robust system solutions.

In our new blog post, we highlight the most important properties of PE and PVC compared to traditional materials, show key areas of application and explain how the materials meet the technical requirements.

Similarities and physiological properties of PE and PVC at a glance

PE and PVC are thermoplastics that both have exceptional technical and physiological properties. One of their greatest strengths is their high chemical resistance, which makes the materials resistant to aggressive substances such as acids, alkalis and salty solutions, making them ideal for transporting chemicals. While PE also copes well with organic media such as oils, PVC shows particular strength in combination with inorganic substances.

Another advantage of the materials is that they are completely corrosion-free. Unlike steel or concrete pipes, plastic pipes are not susceptible to rust or chemical attack, which significantly extends their service life and minimizes maintenance costs. PE and PVC also score highly in terms of sustainability, as they are 100% recyclable and therefore actively contribute to the circular economy.

However, the materials differ in their mechanical properties. PE is characterized by its high flexibility and impact resistance, which means that it remains permanently reliable even under dynamic loads, such as movements in the ground or temperature fluctuations. PVC impresses with its outstanding dimensional stability and mechanical strength, making it particularly suitable for static applications.

Comparison: Material and possible applications

Despite many similarities, PE and PVC differ in parts of their molecular structure and the resulting mechanical properties. The materials are therefore suitable for very different areas of application.

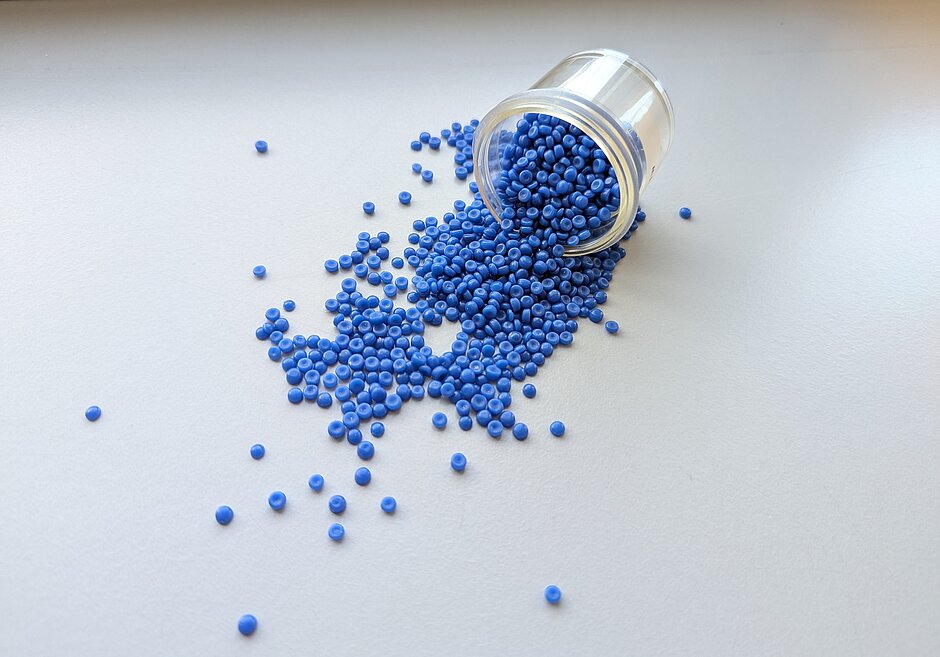

Polyethylene

PE is a semi-crystalline thermoplastic that is available in a wide variety of material types. One variant is PE 100 and the optimized PE 100 RC, which covers a wide range of applications. Pipes made from PE 100 impress with their outstanding creep rupture properties and high resistance to slow and fast crack propagation. The material guarantees a reliable strength of at least 10 MPa at 20 °C and a service life of 50 years. The refined PE 100 RC variant even goes one step further: it has optimized properties that enable an expected service life of up to 100 years in water and gas pipe systems.

In addition, PE 100 RT (Raised Temperature) is specially designed for increased temperature requirements. The material can withstand temperatures of up to 70 °C over a service life of 50 years and can even be used at up to 90 °C for short periods. In addition to their outstanding thermal properties, PE pipes are also characterized by their flexibility and chemical resistance. This makes them ideal for applications with dynamic loads.

Polyvinyl chloride

PVC is an amorphous thermoplastic that is available in various material types. At Westfälische Kunststofftechnik, we use PVC-U and PVC-C in particular, which have proven themselves in various areas of application. PVC-U (U = unplasticized) is a plastic in which a special hardness is achieved by omitting the corresponding plasticizers; this also results in its physiological harmlessness. These properties make PVC-U particularly suitable for drinking water supplies and the food industry. PVC-U also has excellent chemical resistance, making it ideal for transporting chemicals. The material is also easy to process thanks to the possibility of simple bonding.

The temperature application limits of PVC-U range from 0 °C to 45 °C, although it can withstand temperatures of up to 60 °C for short periods. Chlorinated PVC-C is used for higher thermal requirements. The addition of chlorine significantly increases the temperature resistance of the material, making it suitable for temperatures of up to 95 °C. The combination of chemical resistance, dimensional stability and increased heat resistance makes PVC-C ideal for industrial applications, particularly in the chemical industry.

Conclusion: Optimal solutions for individual requirements

WKT's diverse product range offers solutions for a wide variety of applications. Our PE pipes are ideal for use in infrastructure and impress with their flexibility and durability, while our PVC pipes are preferably used in industrial applications where the focus is on dimensional stability and strength.

The excellent chemical resistance, corrosion resistance and durability of the plastics used ensure not only sustainable use, but also a cost-effective solution for industrial and public projects. With our material expertise, we ensure that your systems meet the highest requirements and function reliably in the long term.

This broad product range is complemented by our custom-made products, which can be individually finished in our in-house plastics workshop. We therefore offer a comprehensive portfolio of various high-quality plastic pipes, making us a reliable partner for demanding plastic applications.

Would you like to find out more about our PE and PVC plastic pipe variants? Then get in touch with us. Together we will find the right product solution for your project. You can find all the information about our products in advance here.